Abrasion Resistance Plate: The Backbone of Durability in Heavy Industries

In the world of heavy machinery, construction, and manufacturing, there’s one silent enemy that never rests — wear and tear. Over time, friction, impact, and continuous material flow can erode even the toughest metals, leading to reduced efficiency and costly downtime.

That’s where the Abrasion Resistance Plate steps in — a remarkable innovation that helps industries fight back against mechanical wear, extending equipment life and saving thousands in maintenance costs.

Whether you’re in mining, cement, agriculture, or energy, understanding Abrasion Resistance Plates — their features, applications, and sourcing — can make a world of difference to your operation’s performance and profitability.

What Is an Abrasion Resistance Plate?

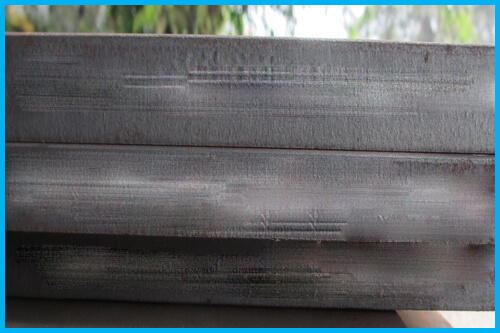

An Abrasion Resistance Plate, often called an AR Plate, is a high-strength steel plate engineered to resist wear, friction, and surface damage caused by constant impact or sliding contact.

In simpler terms, it’s like giving your equipment a tough, protective shield — one that absorbs the punishment so the machinery doesn’t have to.

These plates are made from alloys that offer exceptional hardness and durability, often measured on the Brinell Hardness Scale (BHN). Common grades include AR400, AR450, and AR500, where the numbers indicate hardness levels.

(???? Visual Suggestion: Include a chart comparing AR plate hardness levels — AR400 vs. AR500 — and their typical applications.)

Why Abrasion Resistance Matters

Before diving into the technicalities, let’s pause for a moment. Why is abrasion resistance so important in the first place?

Every time bulk material like rock, ore, or gravel moves across metal surfaces, it causes small scratches, grooves, and chips. Over time, this microscopic damage adds up, leading to:

-

Equipment failure

-

Unscheduled maintenance

-

Productivity loss

-

Increased operational costs

Using Abrasion Resistance Steel Cold Rolled Plates dramatically reduces this wear, ensuring longer-lasting machinery and consistent performance.

How Abrasion Resistance Plates Work

The secret behind the strength of an Abrasion Resistance Plate lies in its metallurgical composition and heat treatment process. These plates are engineered to achieve:

-

High hardness (typically 360–600 BHN)

-

Superior toughness

-

Excellent impact strength

-

Good weldability and formability

This unique combination makes them ideal for high-wear environments where standard structural steel would fail quickly.

Applications of Abrasion Resistance Plate

From mining to agriculture, the Abrasion Resistance Plate is a vital component in protecting industrial equipment. Let’s explore where it’s commonly used.

1. Mining and Quarrying

In mining operations, machinery faces continuous impact and sliding abrasion from hard rocks and minerals. Abrasion Resistance Plates are used in:

-

Dump truck liners

-

Chutes and hoppers

-

Crushers and conveyors

They ensure that even under extreme conditions, the machinery remains operational longer.

2. Cement and Construction

Cement processing and construction involve materials that wear down equipment rapidly. Using Abrasion Resistance Plates in India in mixers, silos, and loaders significantly extends component life.

3. Power and Energy

In coal handling plants and thermal power stations, Abrasion Resistance Steel Plates are used to line feeders, pulverizers, and ash handling systems.

4. Agriculture and Recycling

Farm equipment like ploughs, blades, and shredders benefit from abrasion-resistant steel, as do recycling machines handling glass, metal, or waste.

(???? Visual Suggestion: Add a cross-industry infographic showing how wear plates are used in mining, cement, and energy sectors.)

Types of Abrasion Resistance Plates

There’s no one-size-fits-all solution when it comes to wear protection. Let’s look at the most common types available through Abrasion Resistance Plate Suppliers and Stockists.

1. AR 400 Plate

Offers a good balance between hardness and formability. Commonly used in construction and light mining applications.

2. AR 450 Plate

Slightly harder and ideal for medium-impact environments like loaders, crushers, and excavators.

3. AR 500 Plate

Extremely hard and designed for high-abrasion situations — like ore processing, shot blasting, or heavy mining operations.

4. Abrasion Resistance Steel Cold Rolled Plates

These offer improved surface finish and dimensional accuracy, suitable for precision applications or environments where uniform thickness is vital.

(???? Visual Suggestion: Include a comparison table showing grade, hardness, and typical applications.)

Choosing the Right Abrasion Resistance Plate

Selecting the right Abrasion Resistance Plate depends on your operation’s specific wear conditions. Here’s a quick guide:

-

Assess the Type of Wear

-

Sliding wear (use AR400 or AR450)

-

Impact wear (use AR450 or AR500)

-

Heat and corrosion wear (consider specialized alloy plates)

-

-

Balance Hardness and Workability

Higher hardness means better wear resistance but less flexibility for fabrication. Choose according to your needs. -

Source from Reliable Suppliers

Always work with Authorised Distributors of Abrasion Resistance Plate or Abrasion Resistance Plate Suppliers in India to ensure genuine material and full traceability. -

Consider After-Sales Support

Reputed Abrasion Resistance Plate Dealers offer installation advice, technical support, and MTC certification — crucial for industrial projects.

India’s Growing Market for Abrasion Resistance Plates

India has emerged as a global hub for high-strength and abrasion-resistant steel. With booming infrastructure and manufacturing sectors, the demand for Abrasion Resistance Plate in India has grown exponentially.

1. Abrasion Resistance Plate Suppliers in India

These suppliers provide top-quality AR steel plates from leading mills, offering a wide range of grades and thicknesses to meet industry needs.

2. Abrasion Resistance Plate Stockists in India

Stockists maintain ready inventories for immediate delivery, ensuring that critical projects don’t face delays.

3. Authorised Importers and Distributors

Authorised Importers of Abrasion Resistance Plate in India source plates from reputed global steelmakers like SSAB, Dillinger, and JFE.

Meanwhile, Authorised Distributors of Abrasion Resistance Plate in India ensure quality control, certification, and genuine product assurance.

4. Traders and Dealers

Abrasion Resistance Plate Traders in India and Dealers in India play a key role in connecting manufacturers with end-users across construction, mining, and engineering sectors.

(???? Visual Suggestion: Add a map of India showing major distribution hubs for abrasion-resistant steel — Mumbai, Pune, Chennai, and Kolkata.)

Case Study: Extending the Life of a Mining Conveyor

A mining company in Odisha was facing high maintenance costs due to frequent wear in its conveyor chute liners. The company switched to AR 450 Abrasion Resistance Plates, resulting in:

-

300% increase in liner life

-

50% reduction in maintenance downtime

-

Significant cost savings within the first operational quarter

This case highlights how the right material selection can transform operational efficiency.

Advantages of Using Abrasion Resistance Plates

Here’s why businesses across industries are investing in AR steel:

-

Longer Equipment Life: Reduces replacement frequency

-

Enhanced Productivity: Less downtime and smoother operation

-

Cost Efficiency: Saves on repairs and maintenance

-

Superior Performance: Handles extreme conditions effortlessly

-

Sustainability: Extends equipment lifespan, reducing waste

(???? Visual Suggestion: Add a before-and-after image comparison showing wear reduction after AR plate installation.)

Why Partner with Authorised Suppliers

Not all plates are created equal — or sold equally. Sourcing from Authorised Suppliers of Abrasion Resistance Plate in India ensures you get:

-

Genuine material from certified mills

-

Complete documentation and testing reports

-

Expert technical support

-

Guaranteed performance

Unverified suppliers may offer cheaper products, but inferior steel can compromise safety and efficiency — costing much more in the long run.

Maintenance Tips for Abrasion Resistance Plates

To get the most out of your AR plates, keep these best practices in mind:

-

Regular Inspection: Look for thinning or cracking.

-

Proper Installation: Ensure correct alignment to distribute wear evenly.

-

Avoid Overheating During Welding: Follow manufacturer-recommended preheat and postheat temperatures.

-

Plan Timely Replacement: Replace before the plate wears out completely to avoid equipment damage.

(???? Visual Suggestion: Create an infographic checklist for maintenance routines.)

The Future of Abrasion-Resistant Materials

With innovation driving materials science, the next generation of Abrasion Resistance Plates will feature:

-

Nano-coated surfaces for enhanced friction control

-

Hybrid composites combining toughness and lightweight design

-

Recyclable steel alloys that reduce environmental impact

These developments promise even greater efficiency and sustainability for global industries.

Conclusion: Build for Strength, Design for Longevity

At the end of the day, durability isn’t just about toughness — it’s about smart engineering. The Abrasion Resistance Plate represents that philosophy perfectly, combining strength, efficiency, and longevity in one solution.

Whether you’re sourcing from Abrasion Resistance Plate Suppliers in India, partnering with Authorised Importers, or consulting Abrasion Resistance Plate Traders, always prioritize quality, certification, and expertise.